Introduction

Accidents related to chemical process operations have resulted in loss of human lives, assets, business interruptions, and has negative reputation on the company. The paper is going to highlight how deficiency in compliance audit can lead to catastrophic incidents. Process Safety Management program is a performance standard and the paper will summarize the recognized best practice for performing safety audit reviews using William Geismar Incident as a case study.

OSHA 1910.119 [1]

This regulation issued by the U.S. Department of Labor's Occupational Safety and Health Administration (OSHA). The regulation is designated as OSHA 1910.119, Process Safety Management of Highly Hazardous Chemicals. Its purpose is to prevent or minimize the consequences of releasing hazardous chemicals in a facility or the environment surrounding a facility. Hazardous chemicals are those that may be toxic, reactive, flammable, explosive, or a combination of these properties. Industries handling hazardous chemicals are required to develop an effective PSM program that protects people, assets, and the planet.

Elements of PSM

These elements are the minimum requirements extracted from OSHA 1910.119 [1] .

Employee Involvement

All employees that play a role in facility operations should be involved in a PSM program. Each of the following elements requires a competent and experienced team of individuals to drive each PSM element.

Process Safety Information (PSI)

The PSI element requires that employers collect and document highly hazardous chemical information. This information pertains to the chemicals, technology, and equipment used in the process. This information should be accessible to all employees.

Process Hazard Analysis (PHA)

A PHA is performed by a team of engineering and maintenance experts that are able to identify, evaluate, and control hazards.

Operating Procedures

Companies should document all operational procedures involving initial start-up, normal operations, temporary operations, and emergency shutdowns.

Training

Employees should be trained on procedures, safety factors, and health hazards specific to the job task.

Contractor

Companies should provide training and provide information about the hazards in the workplace to the contractors.

Pre-Start Up Safety Review (PSSR)

Companies are required to perform a safety review before new or modified facilities begin production, specifically, whenever there is a change in process safety information.

Mechanical Integrity

Routine inspections are required for major process units and equipment, such as pressure vessels, storage tanks, piping systems, relief and vent systems, emergency shutdown systems, control systems and pumps to ensure the mechanical integrity of the component meets requirements. All inspections and tests need to be well-documented and must follow recognized and generally accepted good engineering practices (RAGAGEP).

Routine inspections are required for major process units and equipment, such as pressure vessels, storage tanks, piping systems, relief and vent systems, emergency shutdown systems, control systems and pumps to ensure the mechanical integrity of the component meets requirements. All inspections and tests need to be well-documented and must follow recognized and generally accepted good engineering practices (RAGAGEP).

Hot Work Permit

This mandate requires that employer’s issue hot work permits for personnel performing high-temperature operations on equipment.

This mandate requires that employer’s issue hot work permits for personnel performing high-temperature operations on equipment.

Management Of Change (MOC)

A company needs to have an organized and efficient process for managing procedural changes regarding process chemicals, technology, and/or equipment.

Incident Investigation

Investigations should be performed on incidents that resulted in (or could have resulted in) catastrophic release. It has to be performed within 48 hours from the occurrence of the incident .

Emergency Planning And Response

Companies are required to develop and implement emergency action plans for the entire facility. Emergency plans include procedures for mitigating large and small releases.

Companies are required to develop and implement emergency action plans for the entire facility. Emergency plans include procedures for mitigating large and small releases.

Compliance Audits

Individuals should recertify their credentials at least every three years to keep up-to-date with evolving practices and technology. It is furthermore imperative to have an auditing of the PSM elements to check the effectiveness in a periodical basis. This provides opportunity for deficiency identification and course correction.

Trade Secrets

This mandate ensures that employees involved have access to the information about the process and health risks they may encounter during the job.

CCPS Risk Based Process Safety [2]

The purpose of the RBPS Guidelines is to provide tools that will help process safety professionals build and operate more effective process safety management systems. These guidelines provide guidance on how to design a process safety management system, correct a deficient system, and improve process safety management practices.

The purpose of the RBPS Guidelines is to provide tools that will help process safety professionals build and operate more effective process safety management systems. These guidelines provide guidance on how to design a process safety management system, correct a deficient system, and improve process safety management practices.

Elements of RBPS

These elements can be designed and implemented at varying levels of rigor to optimize process safety management performance, efficiency, and effectiveness.

Commit To Process Safety

- Process safety culture

- Compliance with standards

- Process safety competency

- Workforce involvement

- Stakeholder Outreach

- Process safety culture

- Compliance with standards

- Process safety competency

- Workforce involvement

- Stakeholder Outreach

Understand Hazards And Risk

- Process knowledgeable management

- Hazard identification and risk analysis

- Process knowledgeable management

- Hazard identification and risk analysis

Manage Risk

- Operating Procedures

- Safe Work Practices

- Asset Integrity and Reliability

- Contractor Management

- Training and Performance Assurance

- Management of Change

- Operational Readiness

- Conduct of Operations

- Emergency Management

- Operating Procedures

- Safe Work Practices

- Asset Integrity and Reliability

- Contractor Management

- Training and Performance Assurance

- Management of Change

- Operational Readiness

- Conduct of Operations

- Emergency Management

Learn From Experience

- Incident Investigation

- Measurement and Metrics

- Auditing

- Management Review and Continuous Improvement

- Incident Investigation

- Measurement and Metrics

- Auditing

- Management Review and Continuous Improvement

Auditing [1] [2] [3]

Auditing is an element of most PSM frameworks globally and is a critical element which determines the effectiveness of the PSM program. Audits employ protocols and checklists to verify compliance with regulatory requirements and industry standards. They help to ensure programs are properly designed and implemented. Audits identify program deficiencies so that recommendations can be developed for corrective action. Without regular audits, programs will not stay current and will deteriorate, causing companies to face increased health, safety, and environmental risks.

There are three main phases of the audit:

- Pre-audit: Planning and organizing the audit, establishing the audit objectives, scope and protocol and reviewing the design of the program by examining documentation.

- On-site audit: Conducting personnel interviews, reviewing records, and making observations to assess program implementation.

- Post-audit: Briefing management on the audit findings, and preparing a report.

Auditing is an element of most PSM frameworks globally and is a critical element which determines the effectiveness of the PSM program. Audits employ protocols and checklists to verify compliance with regulatory requirements and industry standards. They help to ensure programs are properly designed and implemented. Audits identify program deficiencies so that recommendations can be developed for corrective action. Without regular audits, programs will not stay current and will deteriorate, causing companies to face increased health, safety, and environmental risks.

There are three main phases of the audit:

- Pre-audit: Planning and organizing the audit, establishing the audit objectives, scope and protocol and reviewing the design of the program by examining documentation.

- On-site audit: Conducting personnel interviews, reviewing records, and making observations to assess program implementation.

- Post-audit: Briefing management on the audit findings, and preparing a report.

Case Study

William Olefins Plant Explosion And Fire Incident [4]

About the Plant

The Williams Geismar Olefins Plant, which employs approximately 110 people, is located in Geismar, Louisiana, approximately 20 miles southeast of Baton Rouge. Plant produces ethylene and propylene, these chemicals used in petrochemical industries to make variety of products including plastics and antifreeze.

The Williams Geismar Olefins Plant, which employs approximately 110 people, is located in Geismar, Louisiana, approximately 20 miles southeast of Baton Rouge. Plant produces ethylene and propylene, these chemicals used in petrochemical industries to make variety of products including plastics and antifreeze.

Figure 1 Plant Layout from Google Earth

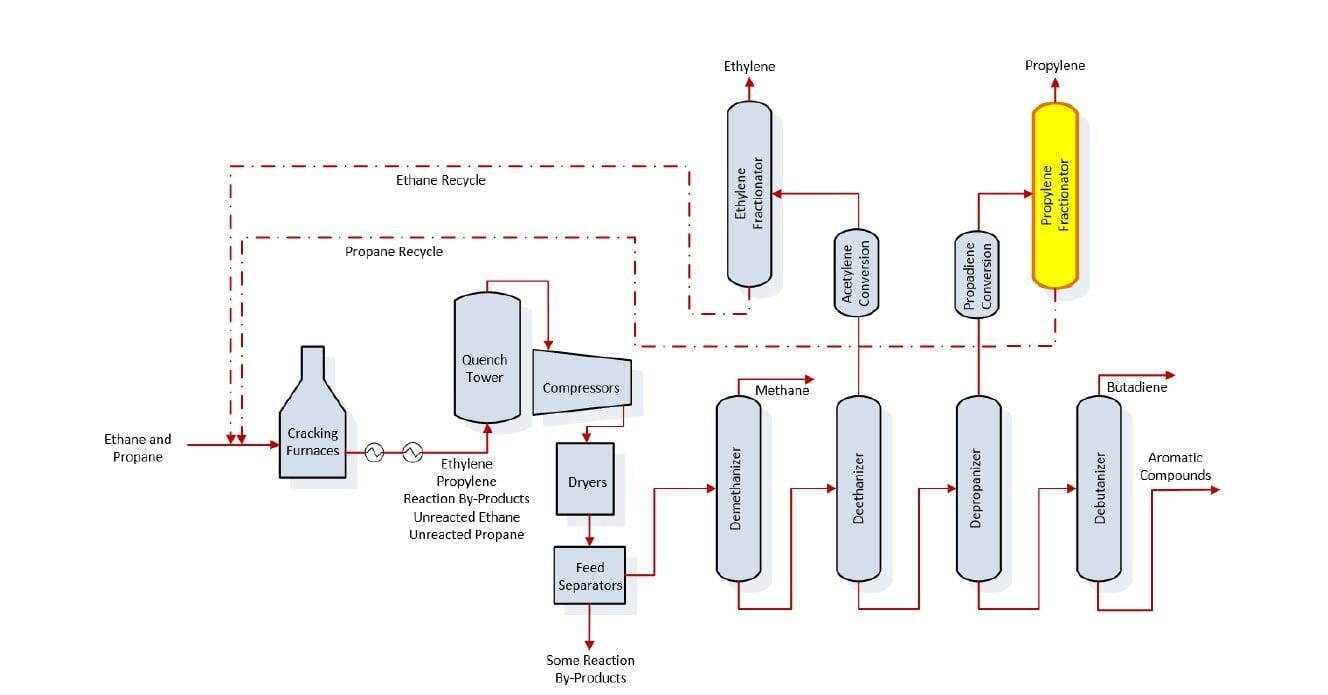

Process Description

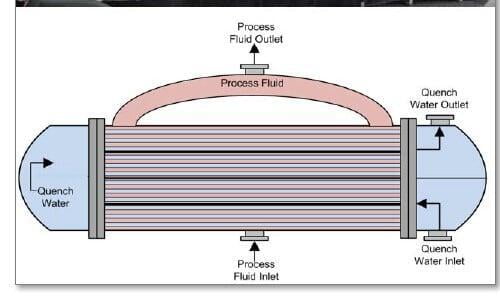

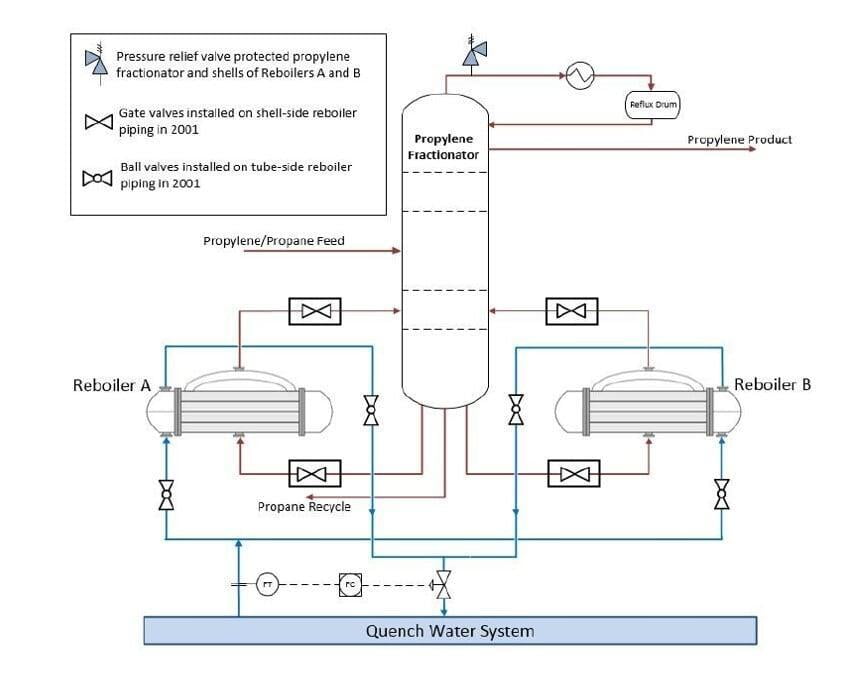

Within the Williams Process, is a distillation column called propylene fractionator, it separates a mixture of propane and propylene. Heat exchangers called reboilers supply heat to the fractionator to boil the propane and propylene mixture, which is essential to separation process. The reboilers are shell and tube heat exchangers. Hot water flows through the tubes, heating and vaporizing propane that flows through the shell and back to the propylene fractionator.

Within the Williams Process, is a distillation column called propylene fractionator, it separates a mixture of propane and propylene. Heat exchangers called reboilers supply heat to the fractionator to boil the propane and propylene mixture, which is essential to separation process. The reboilers are shell and tube heat exchangers. Hot water flows through the tubes, heating and vaporizing propane that flows through the shell and back to the propylene fractionator.

Figure 2 Flow diagram of the process [4]

Figure 3 Reboiler Design [4]

Process Description

On June 13th, 2013, during daily meeting with operations and maintenance personnel, the Williams plant manager noticed that the water flowrate through the operating reboiler had dropped gradually over the past day. The operation supervisor informed the group that he would try to identify the problem, he went into the plant to evaluate the water flowrates, the operation supervisor informed several personnel that fouling within the reboiler could be the problem, that they might need to switch the reboiler. He attempted to meet with his managers so they could get necessary maintenance and operation personnel involved who would perform the work. But his manager was not available, operations supervisor returned to the field and opened the water valves on the stand by reboiler, hot water began flowing inside, but the valves blocking the reboiler from its protective pressure relief valves remained closed. Unknown to the operations supervisor the standby reboiler contained flammable liquid propane that had accumulated during the reboiler was out of service. The hot water heated the liquid propane confined inside the reboiler and pressure increased leading to the rupture of the reboiler. A Boiling Liquid Expanding Vapor Cloud Explosion (BLEVE) resulted in the reboiler rupture, the release fluid ignited to create a massive fireball.

On June 13th, 2013, during daily meeting with operations and maintenance personnel, the Williams plant manager noticed that the water flowrate through the operating reboiler had dropped gradually over the past day. The operation supervisor informed the group that he would try to identify the problem, he went into the plant to evaluate the water flowrates, the operation supervisor informed several personnel that fouling within the reboiler could be the problem, that they might need to switch the reboiler. He attempted to meet with his managers so they could get necessary maintenance and operation personnel involved who would perform the work. But his manager was not available, operations supervisor returned to the field and opened the water valves on the stand by reboiler, hot water began flowing inside, but the valves blocking the reboiler from its protective pressure relief valves remained closed. Unknown to the operations supervisor the standby reboiler contained flammable liquid propane that had accumulated during the reboiler was out of service. The hot water heated the liquid propane confined inside the reboiler and pressure increased leading to the rupture of the reboiler. A Boiling Liquid Expanding Vapor Cloud Explosion (BLEVE) resulted in the reboiler rupture, the release fluid ignited to create a massive fireball.

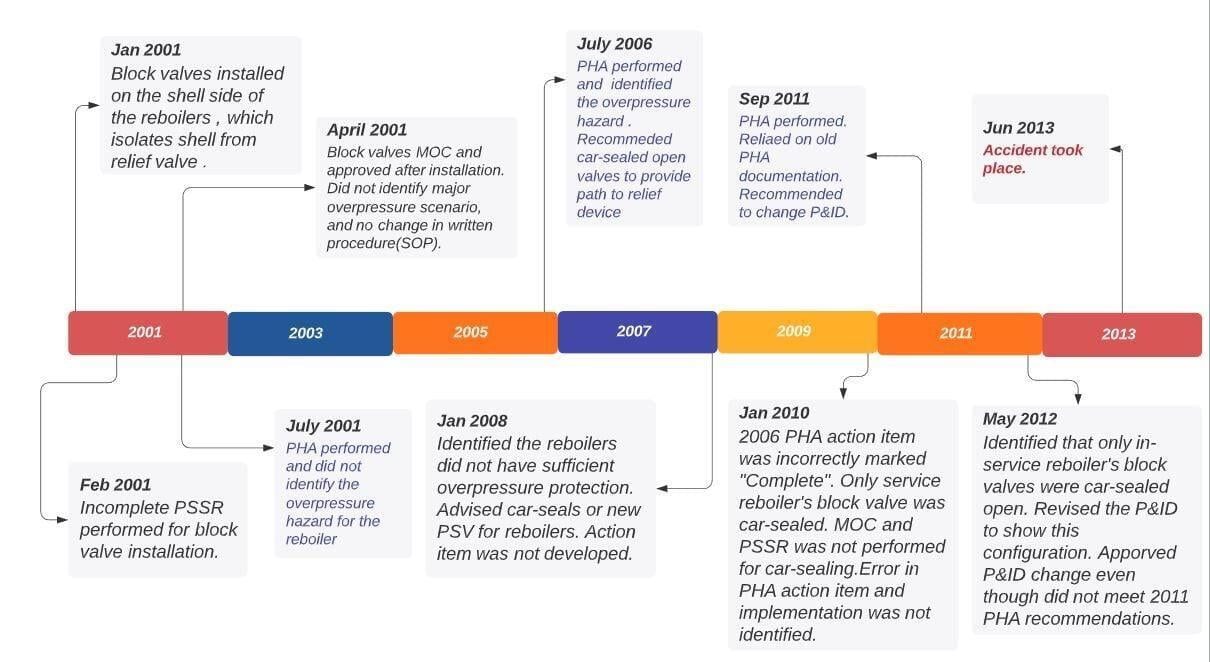

Installation of block valves on the shell side of the exchanger

The water that flows through the tubes of the exchanger contain a small amount of oily tar which condenses into the water earlier in the process. Over time the oily tar from the water builds up the walls of the reboiler tubes, resulting in fouling. Periodic cleaning of tubes by shutting down, there by increasing the heat transfer efficiency. The original propylene fractionator design had both reboilers running simultaneously but in that configuration the fractionator needs to be shut down, when reboiler had been fouled and needed cleaning. To prevent shut down of the propylene fractionator each time the reboilers need to be cleaned, a block valve was installed for ease of changeover of exchangers. In 2001, new valves were installed on each reboiler to allow for operations of only one reboiler at a time. The other reboiler was on standby, clean, and ready to use. But unforeseen at that time these valves introduced a serious hazard, they isolated the standby reboiler from its protective pressure relief valve located on top of the fractionator.

The water that flows through the tubes of the exchanger contain a small amount of oily tar which condenses into the water earlier in the process. Over time the oily tar from the water builds up the walls of the reboiler tubes, resulting in fouling. Periodic cleaning of tubes by shutting down, there by increasing the heat transfer efficiency. The original propylene fractionator design had both reboilers running simultaneously but in that configuration the fractionator needs to be shut down, when reboiler had been fouled and needed cleaning. To prevent shut down of the propylene fractionator each time the reboilers need to be cleaned, a block valve was installed for ease of changeover of exchangers. In 2001, new valves were installed on each reboiler to allow for operations of only one reboiler at a time. The other reboiler was on standby, clean, and ready to use. But unforeseen at that time these valves introduced a serious hazard, they isolated the standby reboiler from its protective pressure relief valve located on top of the fractionator.

Figure 4 Propylene fractionator scheme at the time of incident [4]

Deficiencies Identified

Management of Change (MOC)

- In 2001, Williams performed one MOC to cover the installation of valves on the six quench water heat exchangers identified in the 2000 proposal, including the propylene fractionator Reboiler A and Reboiler B. The Williams MOC process required all the members of different department to consider the potential safety implications of installing the valves. They did this by answering checklist questions used to prompt targeted analysis for each department. While MOC checklists can ensure consideration of common hazards, the Williams MOC reviewers nevertheless did not identify the serious overpressure hazards introduced by installing valves on the reboilers.

- The MOC process is intended to provide a method to identify and control all possible hazards presented by a process change before making the process change in the facility. Williams, however, did not perform an MOC before installing and commissioning the new block valves on the reboilers. The MOC was an after-the-fact activity for Williams to address a regulatory requirement rather than an effective tool used to identify and control new process hazards prior to installing the new equipment.

- MOC reviewers did not identify that the reboilers required overpressure protection because of the introduction of the block valves in the shell side of the reboiler.

- The MOC reviewers incorrectly indicated that existing operating procedures were adequate to account for the new valves, even though there was no procedure specifically for switching the propylene fractionator reboilers. Williams generic procedure was based on the assumption that all reboilers had the process fluid on the tube side of the reboiler, which was not the configuration of the propylene fractionator Reboiler B. As a result, attempting to use this generic procedure to start up Reboiler B could be confusing to workers and could result in initiating an overpressure scenario on the shell side of Reboiler B, a pressure vessel that was not equipped with a protective pressure relief device.

- MOC reviewers improperly indicated that the change did not require a Process Hazard Analysis (PHA), a more robust hazard evaluation option.

- MOC reviewers selected incorrect responses regarding whether the new equipment met all applicable codes and standards. As the overpressure protection did not meet ASME and API standards.

- MOC was not performed for the car seal open of the block valves which was one of the action items in 2006 PHA.

- In 2001, Williams performed one MOC to cover the installation of valves on the six quench water heat exchangers identified in the 2000 proposal, including the propylene fractionator Reboiler A and Reboiler B. The Williams MOC process required all the members of different department to consider the potential safety implications of installing the valves. They did this by answering checklist questions used to prompt targeted analysis for each department. While MOC checklists can ensure consideration of common hazards, the Williams MOC reviewers nevertheless did not identify the serious overpressure hazards introduced by installing valves on the reboilers.

- The MOC process is intended to provide a method to identify and control all possible hazards presented by a process change before making the process change in the facility. Williams, however, did not perform an MOC before installing and commissioning the new block valves on the reboilers. The MOC was an after-the-fact activity for Williams to address a regulatory requirement rather than an effective tool used to identify and control new process hazards prior to installing the new equipment.

- MOC reviewers did not identify that the reboilers required overpressure protection because of the introduction of the block valves in the shell side of the reboiler.

- The MOC reviewers incorrectly indicated that existing operating procedures were adequate to account for the new valves, even though there was no procedure specifically for switching the propylene fractionator reboilers. Williams generic procedure was based on the assumption that all reboilers had the process fluid on the tube side of the reboiler, which was not the configuration of the propylene fractionator Reboiler B. As a result, attempting to use this generic procedure to start up Reboiler B could be confusing to workers and could result in initiating an overpressure scenario on the shell side of Reboiler B, a pressure vessel that was not equipped with a protective pressure relief device.

- MOC reviewers improperly indicated that the change did not require a Process Hazard Analysis (PHA), a more robust hazard evaluation option.

- MOC reviewers selected incorrect responses regarding whether the new equipment met all applicable codes and standards. As the overpressure protection did not meet ASME and API standards.

- MOC was not performed for the car seal open of the block valves which was one of the action items in 2006 PHA.

Pre-Start Up Safety Review(PSSR)

Williams performed a Pre-Startup Safety Review (PSSR) as required by process safety management regulations following the introduction of the block valves. Conducting the Williams PSSR required filling out a 21-question form. Williams reviewers either did not answer or incorrectly answered key PSSR process safety questions. PSSR was not performed for the car seal open of the block valves which was one of the action items in 2006 PHA, which could have provided an opportunity to identify that the PHA action item to car seal open a block valve on both reboilers were not complete.

Williams performed a Pre-Startup Safety Review (PSSR) as required by process safety management regulations following the introduction of the block valves. Conducting the Williams PSSR required filling out a 21-question form. Williams reviewers either did not answer or incorrectly answered key PSSR process safety questions. PSSR was not performed for the car seal open of the block valves which was one of the action items in 2006 PHA, which could have provided an opportunity to identify that the PHA action item to car seal open a block valve on both reboilers were not complete.

Process Hazard Analysis(PHA)

The block valves were installed on the reboilers, to operate one reboiler at a time. PHA done in the year 2001, could not identify the overpressure scenario caused by the block valves. Again, PHA was performed in the year 2006 as part of the revalidation cycle. The PHA team identified the overpressure scenario and recommended car seal opening (CSO) of the outlet block valves. But, 2006 PHA action item was marked complete without car seal open or lock open the block valve. In the year 2011, PHA accepted closure of 2006 action item and depended completely on previous documentation and recommended to update the P&ID which showed that block valves were not car seal open.

The block valves were installed on the reboilers, to operate one reboiler at a time. PHA done in the year 2001, could not identify the overpressure scenario caused by the block valves. Again, PHA was performed in the year 2006 as part of the revalidation cycle. The PHA team identified the overpressure scenario and recommended car seal opening (CSO) of the outlet block valves. But, 2006 PHA action item was marked complete without car seal open or lock open the block valve. In the year 2011, PHA accepted closure of 2006 action item and depended completely on previous documentation and recommended to update the P&ID which showed that block valves were not car seal open.

Relief System Analysis

In 2008, Williams performed a relief valve engineering analysis, to ensure the valves were properly sized for the equipment they were designed to protect. The analysis identified that the propylene fractionator reboilers did not have sufficient overpressure protection. The engineering firm suggested two mitigation options

- Car seal open of the block valves in the inlet/outlet of the reboilers shell side

- Installation of new relief valve to protect the shell side of the reboilers

Since, car seal open of the block valves was one of the action items during 2006 PHA. So, Williams assumed that this was complete. Because the company did not fully implement the 2006 PHA action item, this overpressure hazard remained unmitigated.

In 2008, Williams performed a relief valve engineering analysis, to ensure the valves were properly sized for the equipment they were designed to protect. The analysis identified that the propylene fractionator reboilers did not have sufficient overpressure protection. The engineering firm suggested two mitigation options

- Car seal open of the block valves in the inlet/outlet of the reboilers shell side

- Installation of new relief valve to protect the shell side of the reboilers

Since, car seal open of the block valves was one of the action items during 2006 PHA. So, Williams assumed that this was complete. Because the company did not fully implement the 2006 PHA action item, this overpressure hazard remained unmitigated.

Figure 5 Timeline of events

Key Learnings

- Process Safety Management is a performance standard which requires proper implementation and upkeep of each PSM element.

- Engineers and supervisors should make risk-based decisions when having operational changes

- A robust management of change program is essential and is one of the elements where company still struggle to implement

- Using the hierarchy of controls when evaluating and selecting safeguards to control process hazards, whenever there is a process change.

- Establishing a strong organizational process safety culture, ie. when proper procedures or checklist for PSSR needs to be documented and approved by higher management.

- Developing robust process safety management programs and action item closure management. From time-to-time action items needs to be tracked and had to be closed within reasonable timelines.

- Ensuring continual vigilance in implementing process safety management programs to prevent major process safety incidents. Example audit to be performed at regular intervals.

- Car seal or locked (open/close) valves have to be audited to ensure the integrity of the process.

- Process Safety Management is a performance standard which requires proper implementation and upkeep of each PSM element.

- Engineers and supervisors should make risk-based decisions when having operational changes

- A robust management of change program is essential and is one of the elements where company still struggle to implement

- Using the hierarchy of controls when evaluating and selecting safeguards to control process hazards, whenever there is a process change.

- Establishing a strong organizational process safety culture, ie. when proper procedures or checklist for PSSR needs to be documented and approved by higher management.

- Developing robust process safety management programs and action item closure management. From time-to-time action items needs to be tracked and had to be closed within reasonable timelines.

- Ensuring continual vigilance in implementing process safety management programs to prevent major process safety incidents. Example audit to be performed at regular intervals.

- Car seal or locked (open/close) valves have to be audited to ensure the integrity of the process.

Figure 6 Car seal opening of the valve

Conclusions

Process Safety Management audits have to be performed periodically, to identify if the current safeguards are enough to protect the plant from accidents. A process safety culture is necessary to prevent a checklist mentality to complete PSM initiatives, thorough understanding of the risk, and using risk to make appropriate operational decisions. Adequate process safety training and knowledge to employers and contractors aids in identifying catastrophic incidents. Management should embrace the deficiency and monitor the effectiveness of the PSM program using leading and lagging indicators. PSM audits should document their deficiencies with actionable items with appropriate stakeholders. The audit findings should be accessible to all the employers and the PSM Team must coordinate the closure of all action items. The recommendations provided in such audits have to be implemented and verified by the PSM Team within a reasonable timeline.

Process Safety Management audits have to be performed periodically, to identify if the current safeguards are enough to protect the plant from accidents. A process safety culture is necessary to prevent a checklist mentality to complete PSM initiatives, thorough understanding of the risk, and using risk to make appropriate operational decisions. Adequate process safety training and knowledge to employers and contractors aids in identifying catastrophic incidents. Management should embrace the deficiency and monitor the effectiveness of the PSM program using leading and lagging indicators. PSM audits should document their deficiencies with actionable items with appropriate stakeholders. The audit findings should be accessible to all the employers and the PSM Team must coordinate the closure of all action items. The recommendations provided in such audits have to be implemented and verified by the PSM Team within a reasonable timeline.

References

[1] United States, Department of Labor, Occupational Safety and Health Administration (OSHA), “OSHA 1910.119, Process Safety Management of Highly Hazardous Chemicals,” 8 February 2013. [Online]. Available: https://www.osha.gov/laws- regs/regulations/standardnumber/1910/1910.119.

[2] Center for Chemical Process Safety (CCPS), Guidelines For Risk Based Process Safety, A John Wiley & Sons, Inc. , 2007.

[3] Center for Chemical Process Safety (CCPS), Guidelines for Auditing Process Safety Management Systems, Second Edition, A John Wiley & Sons, Inc. , 2011.

[4] Chemical Safety Board (CSB), “Williams Olefins Plant Explosion and Fire,” 19 October 2016. [Online]. Available: https://www.csb.gov/williams-olefins-plant-explosion-and-fire-/

[1] United States, Department of Labor, Occupational Safety and Health Administration (OSHA), “OSHA 1910.119, Process Safety Management of Highly Hazardous Chemicals,” 8 February 2013. [Online]. Available: https://www.osha.gov/laws- regs/regulations/standardnumber/1910/1910.119.

[2] Center for Chemical Process Safety (CCPS), Guidelines For Risk Based Process Safety, A John Wiley & Sons, Inc. , 2007.

[3] Center for Chemical Process Safety (CCPS), Guidelines for Auditing Process Safety Management Systems, Second Edition, A John Wiley & Sons, Inc. , 2011.

[4] Chemical Safety Board (CSB), “Williams Olefins Plant Explosion and Fire,” 19 October 2016. [Online]. Available: https://www.csb.gov/williams-olefins-plant-explosion-and-fire-/

To read our previous blog, click here : Solving Process Safety Issues with CHEF Calculation Aid